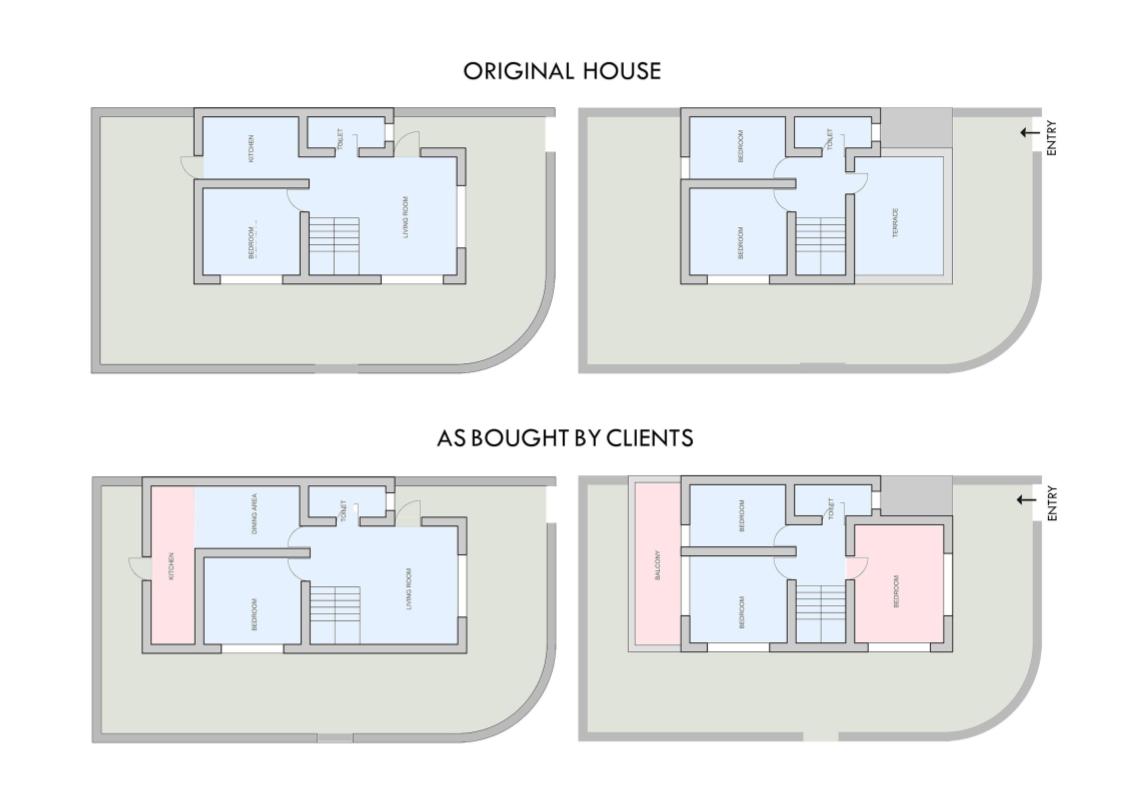

The project is of an independent house. Our client purchased a Row-house in an old housing scheme which was constructed by the erstwhile city developers – CIDCO in the 1980s. The previous owners had renovated the house by extending certain portions. Our clients wanted to develop it as a second home now and eventually a retirement home for later.

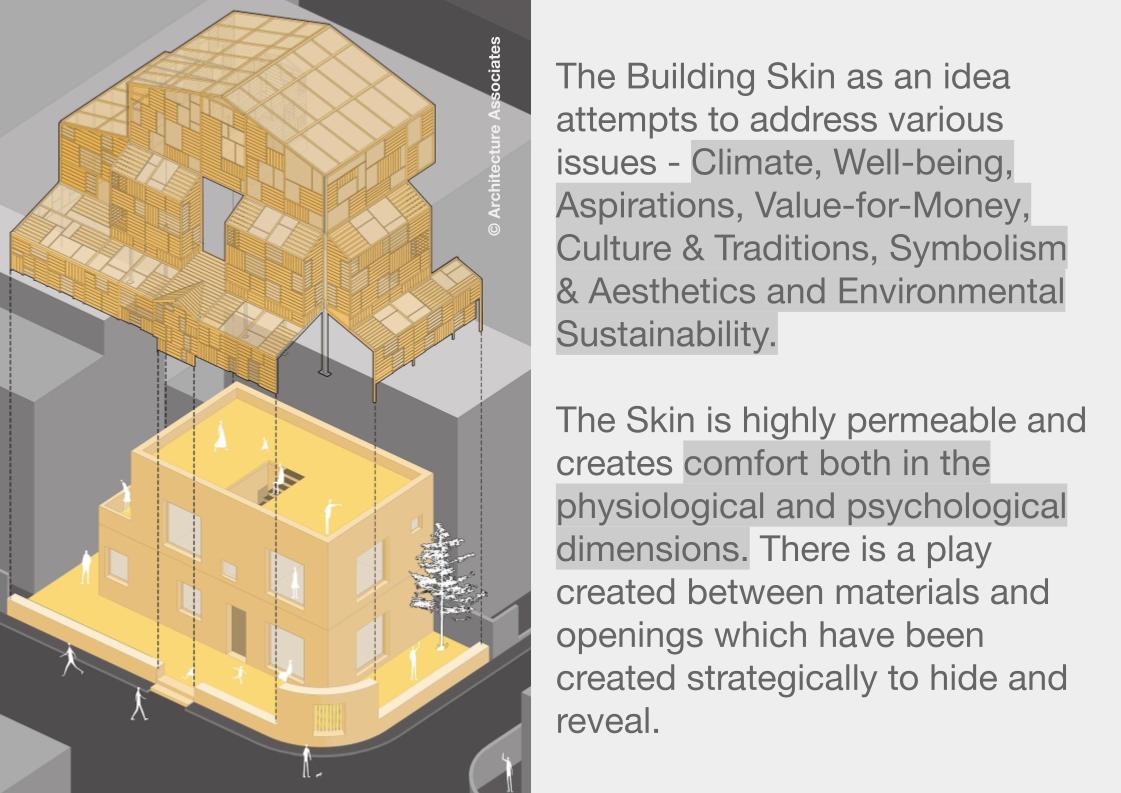

After studying the condition and structure we advised the client to carry out minor repairs and retrofit & adapt it to their needs and aspirations instead of demolishing it and making a new building. We used the structure as it is and created a new envelope over the building and some internal alterations to house their needs and utilities. The resulting Architecture is a completely new building, different & new in essence and appearance.

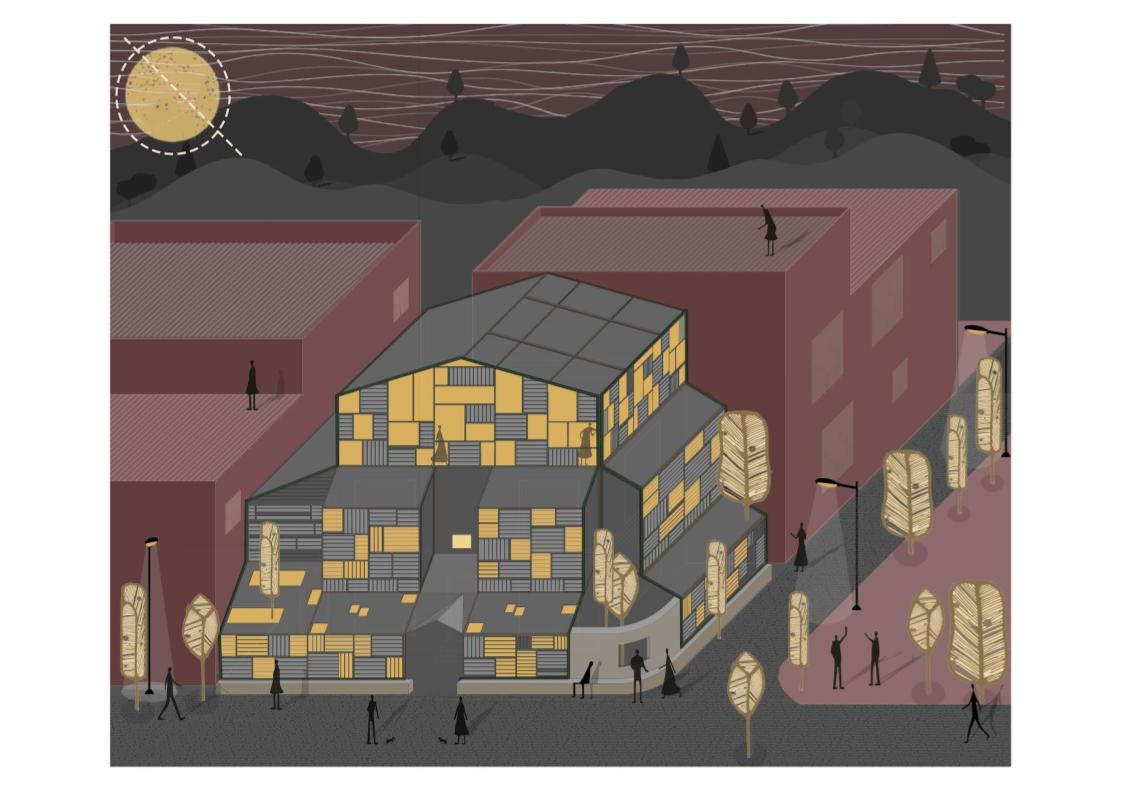

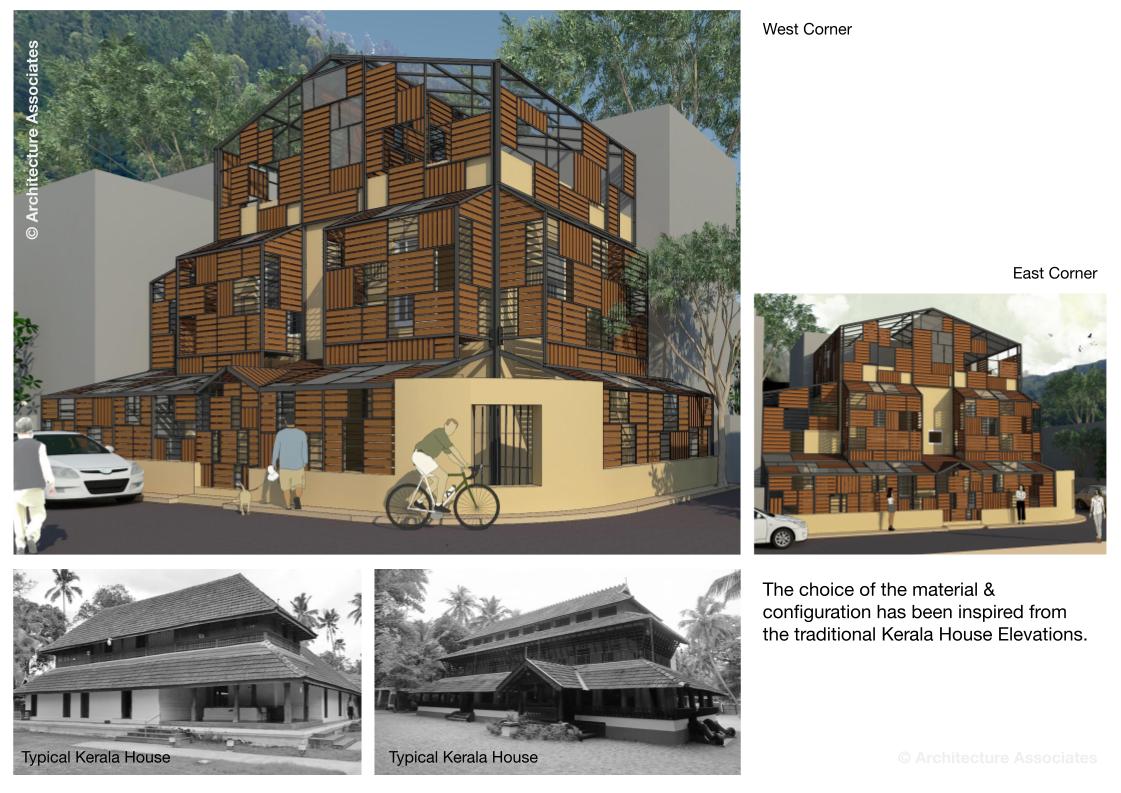

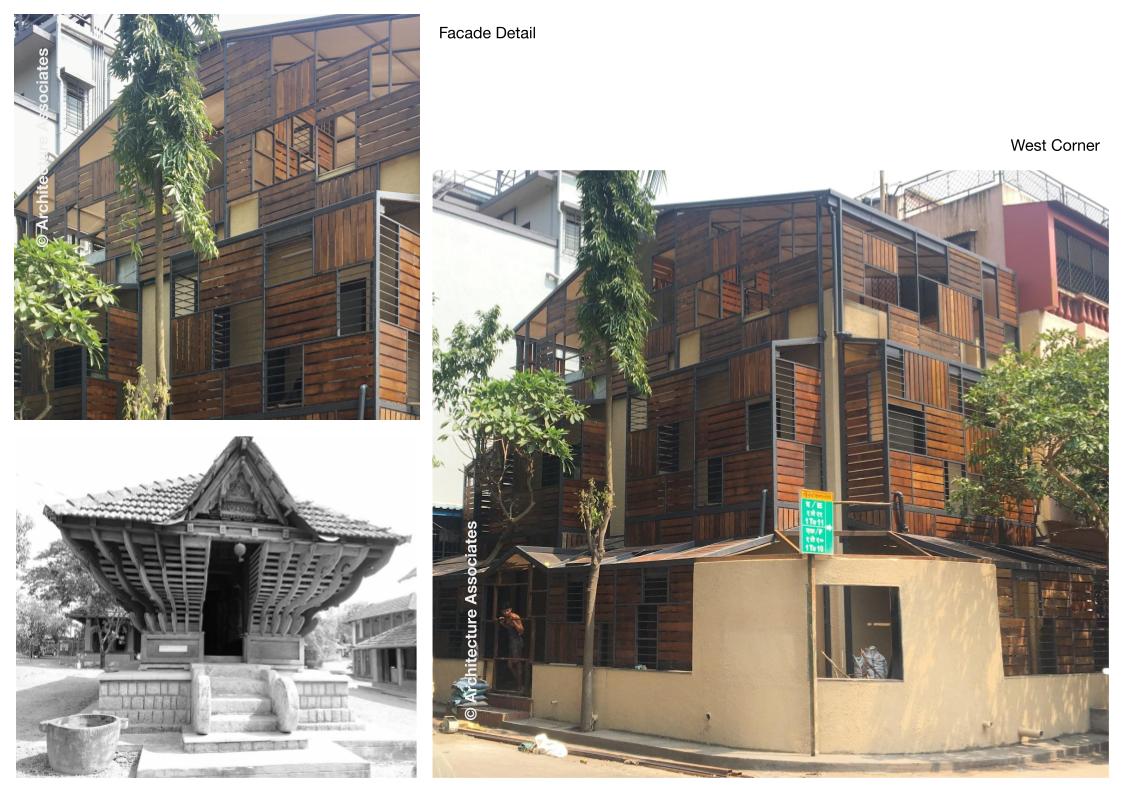

The existing building is primarily made of Brick and RCC. The new skin is made up of Steel structure and Old Teak wood panelling. Twinwall Polycarbonate sheets are used for Roofing cover.

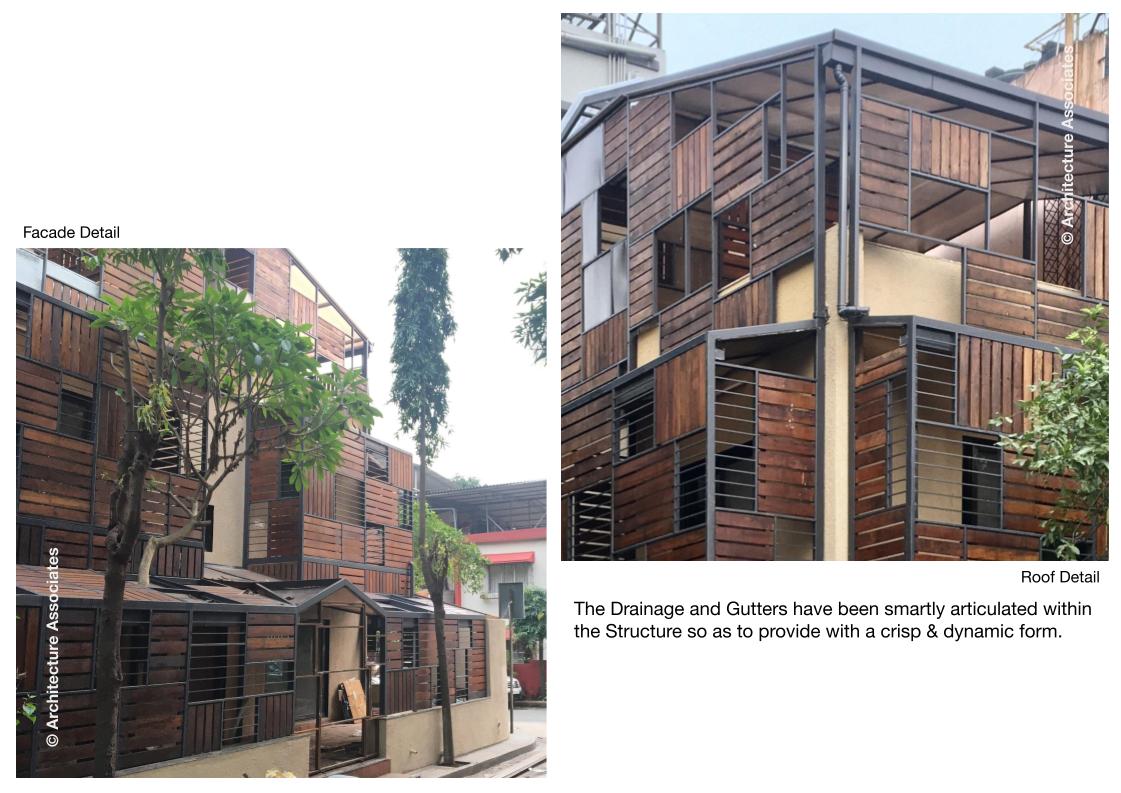

The primary decision to adapt the existing building has helped considerably reduce time, energy & material for construction. The Foundations, Plinth & Filling, Walls & Structure, Floor Slabs have been renewed by conducting treatments and new finishes. The structure has been made lighter by creating more & larger openings. Most of the new building material too is Natural or recycled. Steel has been used as a structural element for the skin. Recycled wood as panels and Multi-wall polycarbonate sheets for roofing has also helped decrease load and hence reduced the quantum of steel required. The recycled wood has been treated and finished using linseed oil. The floors of the house have been done by use of natural stones.

Environmental Sustainability

Progress – Adaptive Reuse

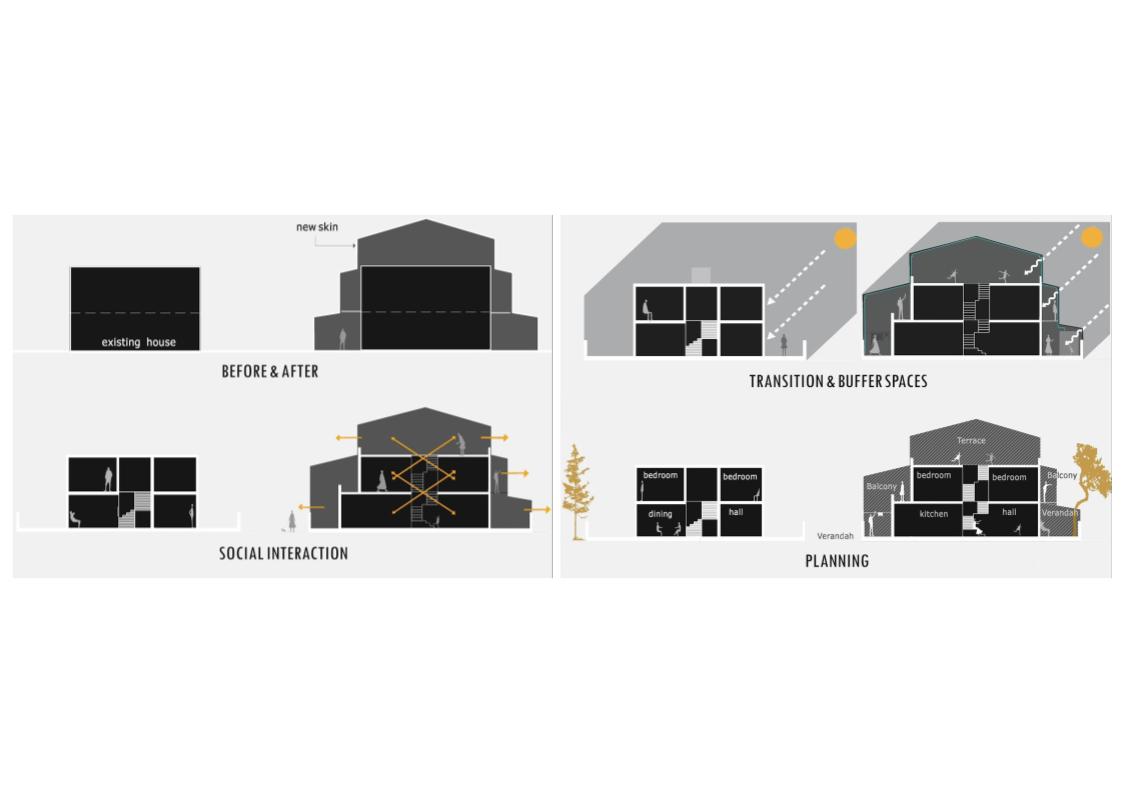

The existing house had a typical design and was Socially, Climatically and Culturally agnostic. The focus then was on cost effective and timely construction. The structure was built using a hybrid system of load bearing and RCC Columns, Beams and Slabs. We appreciated the quantum of space inside and outside the old structure and burrowed out the new spaces by securing the structure suitably using steel girders. At various places we provided for a new building skin which was made using MS box sections. These were predominantly supported on new foundations, which eliminated any new load on the old structure.

People – Socially Inclusive

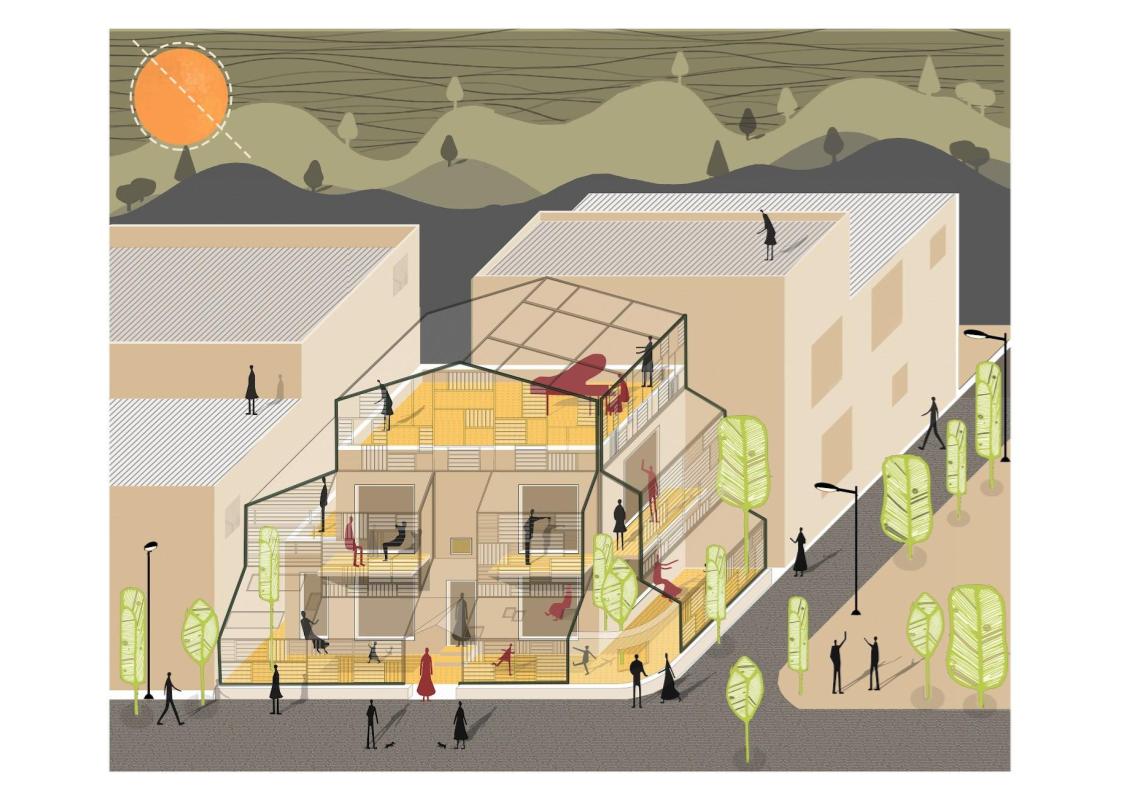

The old house design was socially exclusive by virtue of very few openings within and outside the house. To increase interactivity we created many openings so as to offer interaction within the house and with the street outside. A covered verandah on the ground floor, balconies on the first floor and pavillion on the top created usable spaces and enabled interaction with the outside. An open plan of the inside also increased interaction within the house. The building skin is articulated with wooden slats which were strategically composed to maintain privacy within the new house. Large windows on the inside help regulate privacy within the house.

People, Planet, Place – Climate & Material

The new building skin is made of MS Box section as structure and support for the infill. The vertical surfaces are filled with Wooden slats and the horizontal & inclined surfaces have an additional layer of transparent Polycarbonate sheets to block rain water. The wood was sourced from the informal building recycling industry and is around 50 years old. Slats were stripped out of thicker elements and composition of the slats is designed so as to minimise the wastage in material and labour. The form of the skin is reminiscent of a traditional house type from the region of Kerala, the native of the clients. The climate type of both Kerala and current location is similar – Tropical / Hot & Humid.